Medical Device Repair Depot in Canada

Fast, traceable electronics repair & refurbishment for OEMs and healthcare networks, without cross-border delays.

Devices & Subassemblies We Repair (Electronics-Focused)

We focus on non-implantable, non-life-supporting electrical/electronic medical equipment and peripherals used in clinics, hospitals, and diagnostic centres. Full scope is finalized in your SOW.

Patient Monitoring

- Bedside patient monitors, central stations, telemetry receivers

- SpO₂, NIBP, ECG/ETCO₂ modules & cables

- Power supplies, user I/O boards, display assemblies

- Ventilator & Respiratory (Electronics Only)

- Control/UI boards, power supplies, display & keypad assemblies

- Battery management PCBs, fan driver boards (No gas-path calibration or clinical performance validation—electronics only.)

ECG / Diagnostic

- ECG/EKG recorders & acquisition modules

- Docking/charging bases, comms modules, printer mechanisms

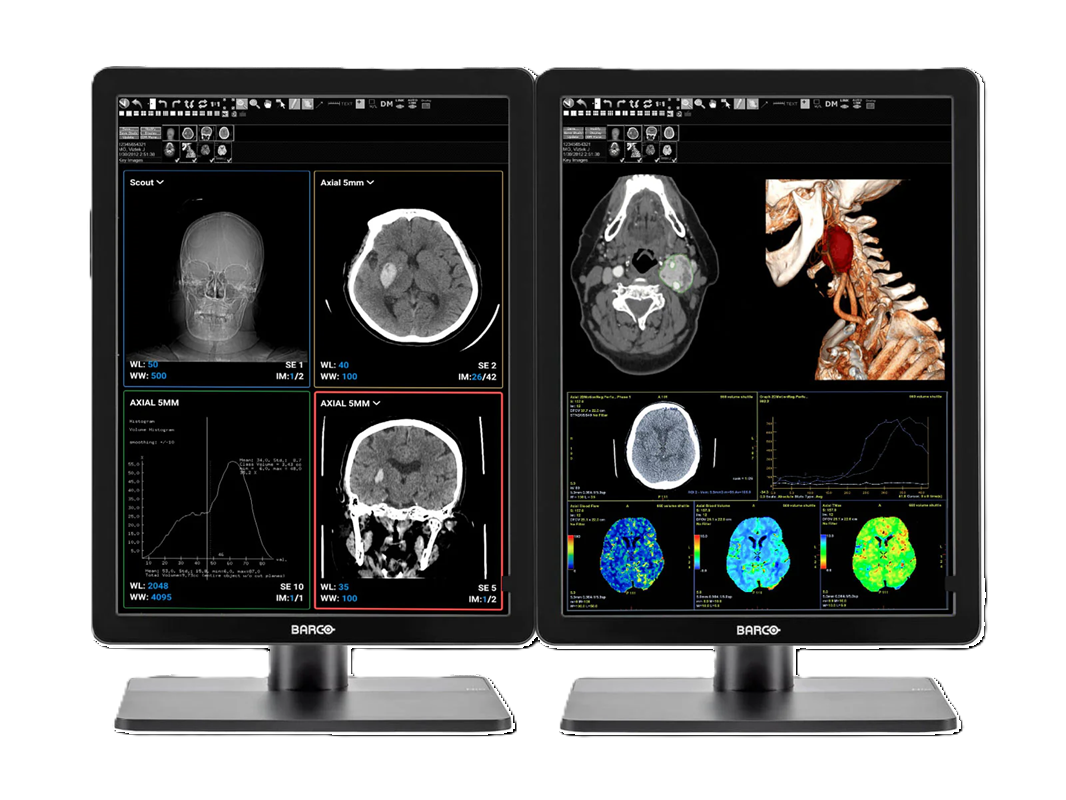

- Medical Monitors & Imaging Peripherals

- Clinical/diagnostic displays (PACS, modality workstations)

- Signal interfaces, backlight drivers, inverter and scaler boards

Point-of-Care IT & Accessories

- Thin clients, tablets, carts electronics, barcode/ID scanners

- Chargers, docking stations, bedside peripherals

- Power & Infrastructure

- External/embedded power supplies, harnesses, relays, connectors

- UPS modules used for carts and bedside systems

Need something specific? Send model numbers and fault symptoms—we’ll confirm coverage and required test fixtures.

Why OEMs Choose a Canadian Depot

When Canadian RMAs leave the country, you lose weeks to freight, brokerage, and border holds. Microland keeps devices in-country, restoring units quickly with component-level repairs, clean documentation, and proactive status updates.

- 5–7 business days average TAT (device-class dependent)

- Board-level repair to reduce replacement spend and e-waste

- Daily status pushes + photo evidence via API/CSV/email

- Serialized traceability (as-found/as-left data, parts, and tests)

- ESD-controlled workstations, calibrated instruments, fixture-based testing

- Canadian parts holding for critical SKUs to avoid back-order stalls

Service Models & SLAs

-

Standard Warranty RMA: 5–7 business days after parts receipt

-

Expedite / NBD Triage: Priority line with pre-positioned spares

-

Parts Holding in Canada: Min/max planning for critical modules

-

Project-Based Refurbishment: Batch programs with yield reporting

-

Reporting: Daily queue snapshot, exception alerts, and monthly KPI pack (TAT, yield, NTF rate, repeat repair rate)

Quality, Compliance & Data

-

Traceability: Device history record per serial (symptom → root cause → corrective action → tests).

-

Test Rigs: We build to your procedures or operate OEM-provided fixtures/jigs.

-

Calibration: Measurement equipment maintained on schedule; logs available.

-

ESD Control: Wrist-strap verification, grounded benches, ESD packaging on ship-out.

-

Decontamination Policy: Incoming units must be decontaminated and labelled by sender; secondary cleaning performed at intake.

How Our Depot Workflow Reduces TAT

- Intake & Triage (Day 0): Barcoded check-in with photo set; RMA/serial captured; “as-received” condition logged.

- Diagnostics: Board-level fault isolation using oscilloscopes, thermal imaging, and functional testers; root-cause notes attached to the serial.

- Repair: Micro-solder, reflow/BGA as appropriate; connectors, passives, and semiconductors replaced to spec.

- Verification: Electrical safety checks and functional testing per OEM procedures; fixture-based where provided.

- Cosmetic & Repack: Clean, presentable returns; accessories matched; tamper seals applied if required.

- Close-Out: As-left photos, parts list, and test records attached; status pushed to your system automatically.

Why Microland Technical Services Is the Partner Brands Trust

For three decades we’ve been the quiet Canadian extension of tier-one audio-video OEMs—Denon, Marantz, Yamaha, Polk, KEF, QSC and more. We invest in specialised test rigs, keep millions in parts on site, and obsess over metrics (average TAT last quarter: 7.5 days).

- We fix what others swap. Board-level saves you > $300 per unit.

- We answer the phone. 97 % first-ring pickup in our call queue.

-

We protect your brand face. We treat your brand as if it was our own.

Stop paying for empty miles and angry customers.

Let’s keep your A/V products—and your reputation—right here in Canada.

Frequently Asked Questions

Do you repair to the component level?

Yes, when safe and appropriate. We routinely replace ICs, connectors, passives, and perform BGA reflow/replacement under microscope control.

Can you integrate with our RMA/CRM?

Yes. We support API, EDI and CSV integrations for status, photos, test data, and part usage tied to serial numbers.

What is your intake policy for contaminated devices?

Units must arrive decontaminated and labelled. We perform secondary exterior cleaning and document condition with photos.

Ready to Scope Your Program?

Request Pricing, or Book a 15-min Discovery Call. We’ll confirm coverage, fixtures, SLAs, and onboarding steps in a single session.